Tooling

Tooling

Custom Projects

ISO Class 7 Cleanrooms

Team Members

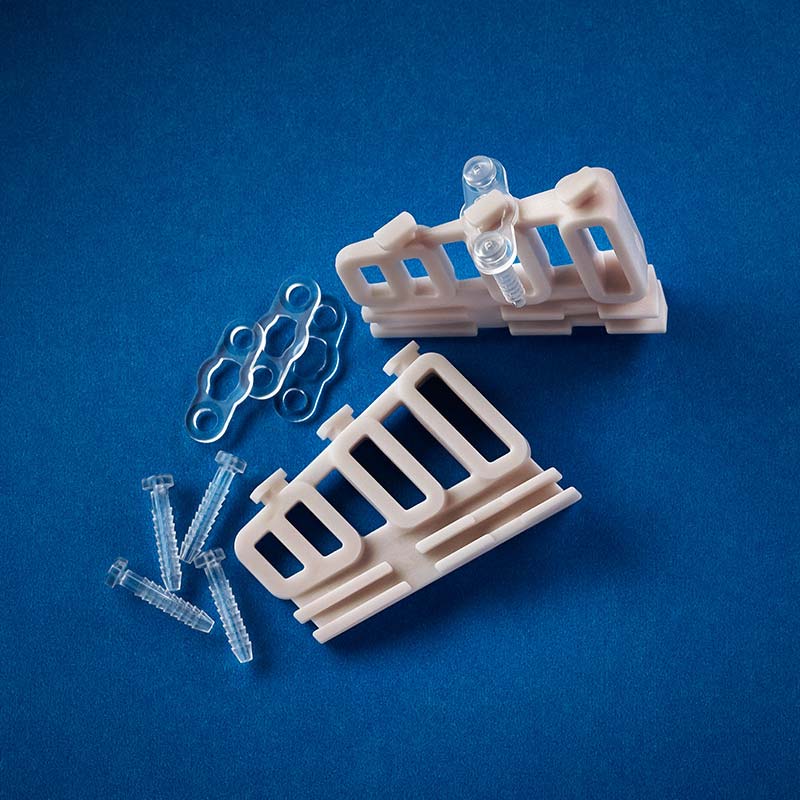

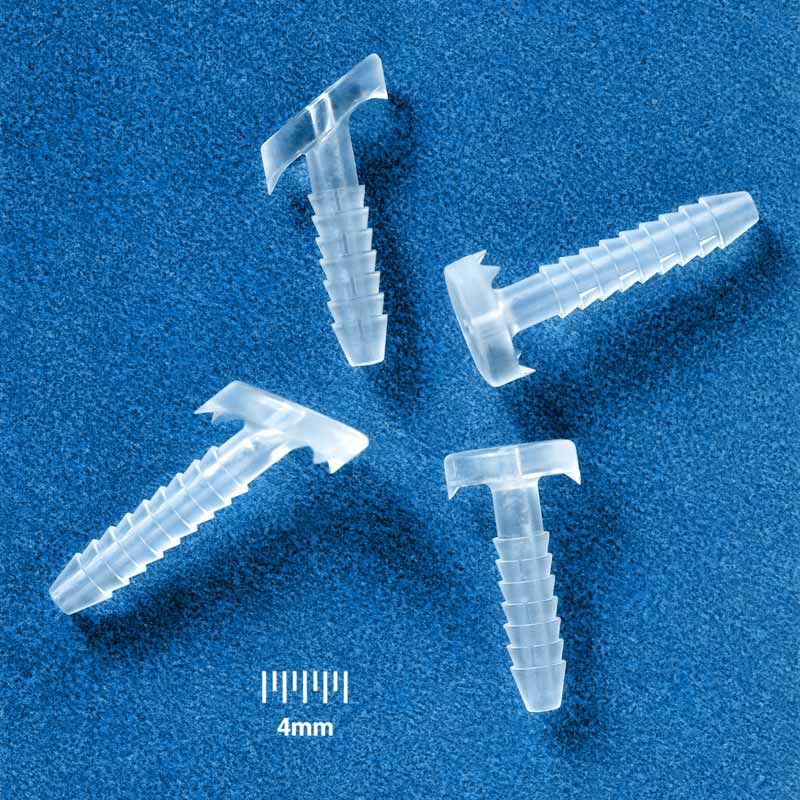

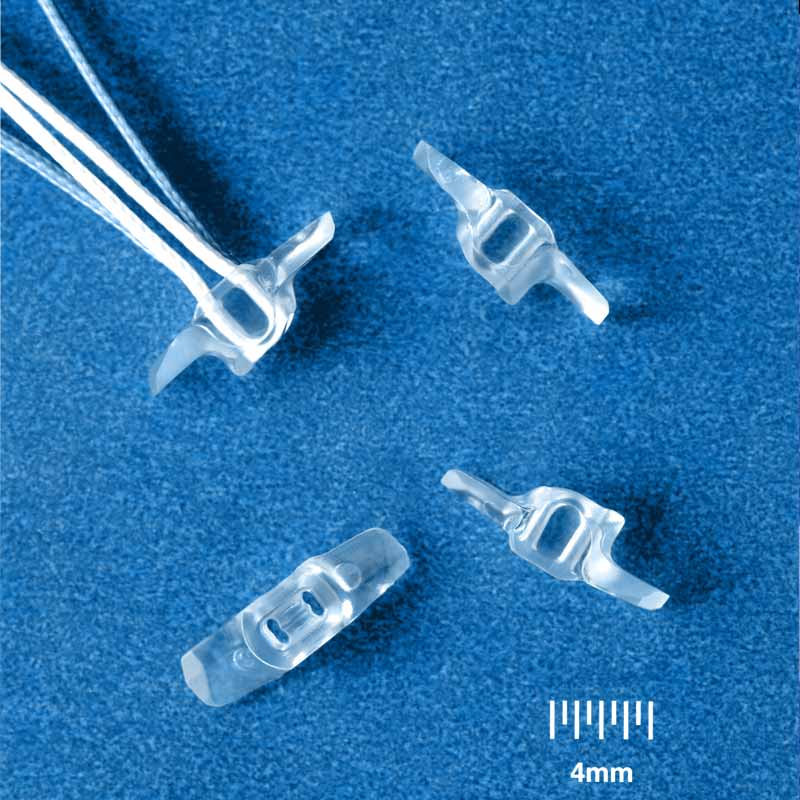

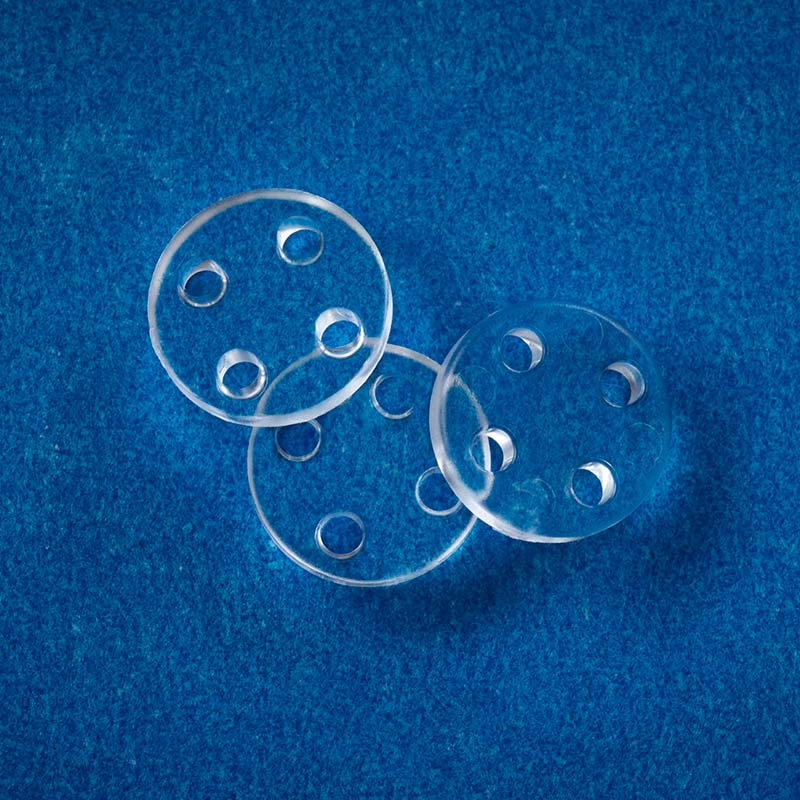

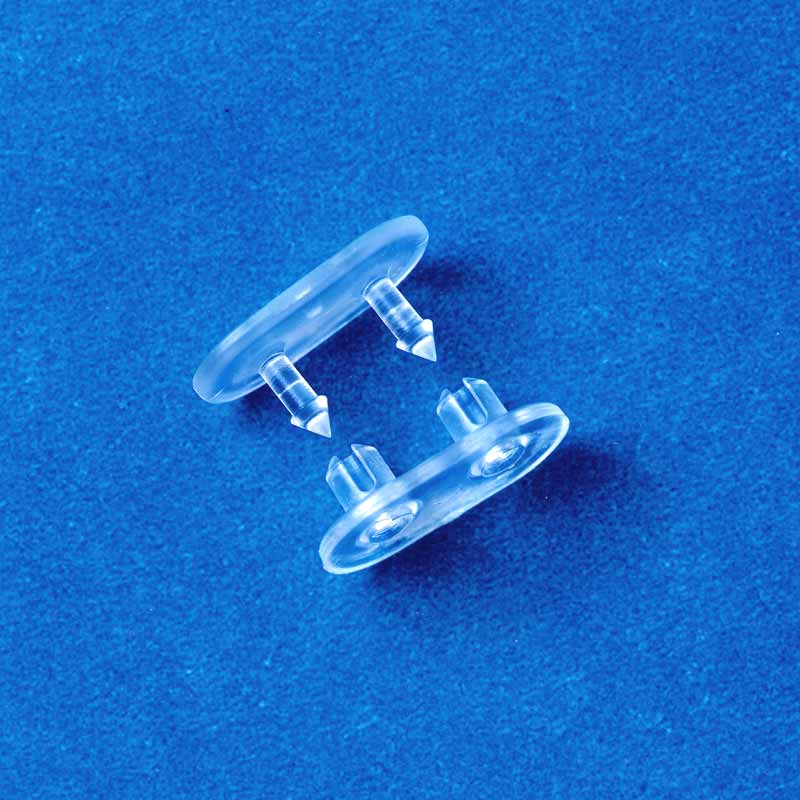

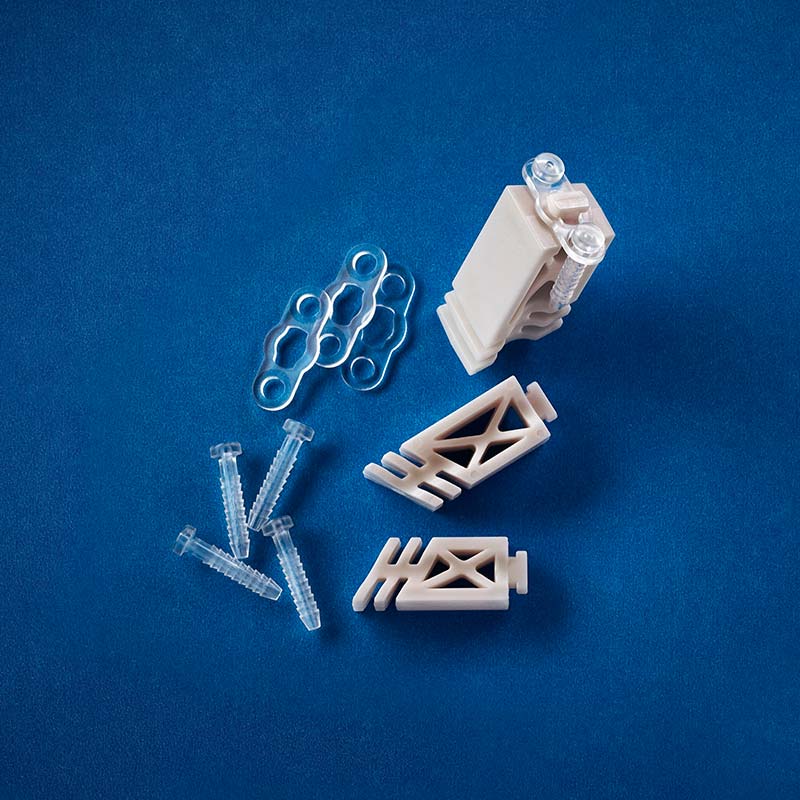

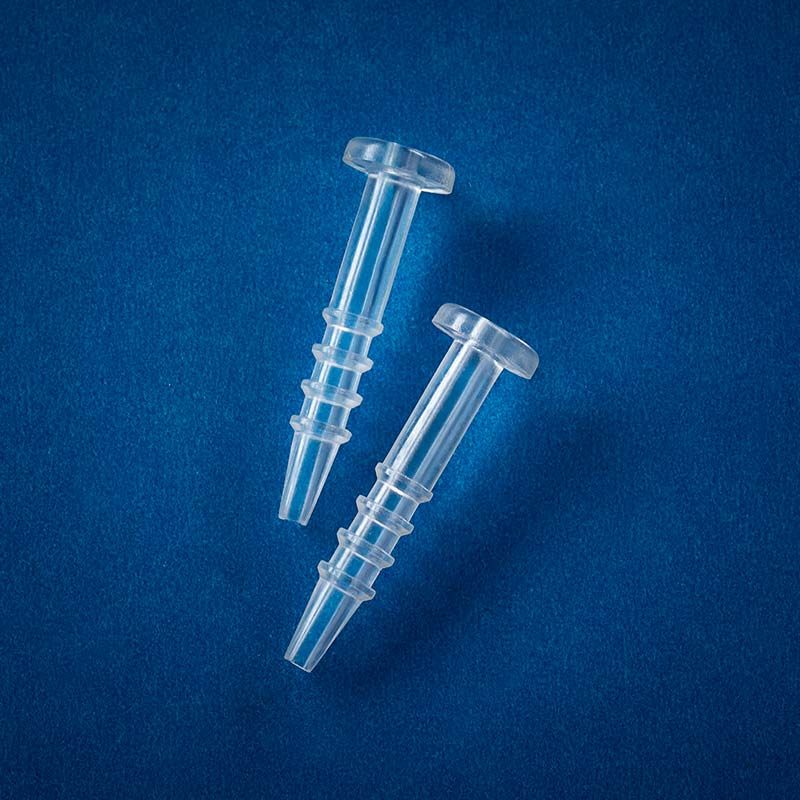

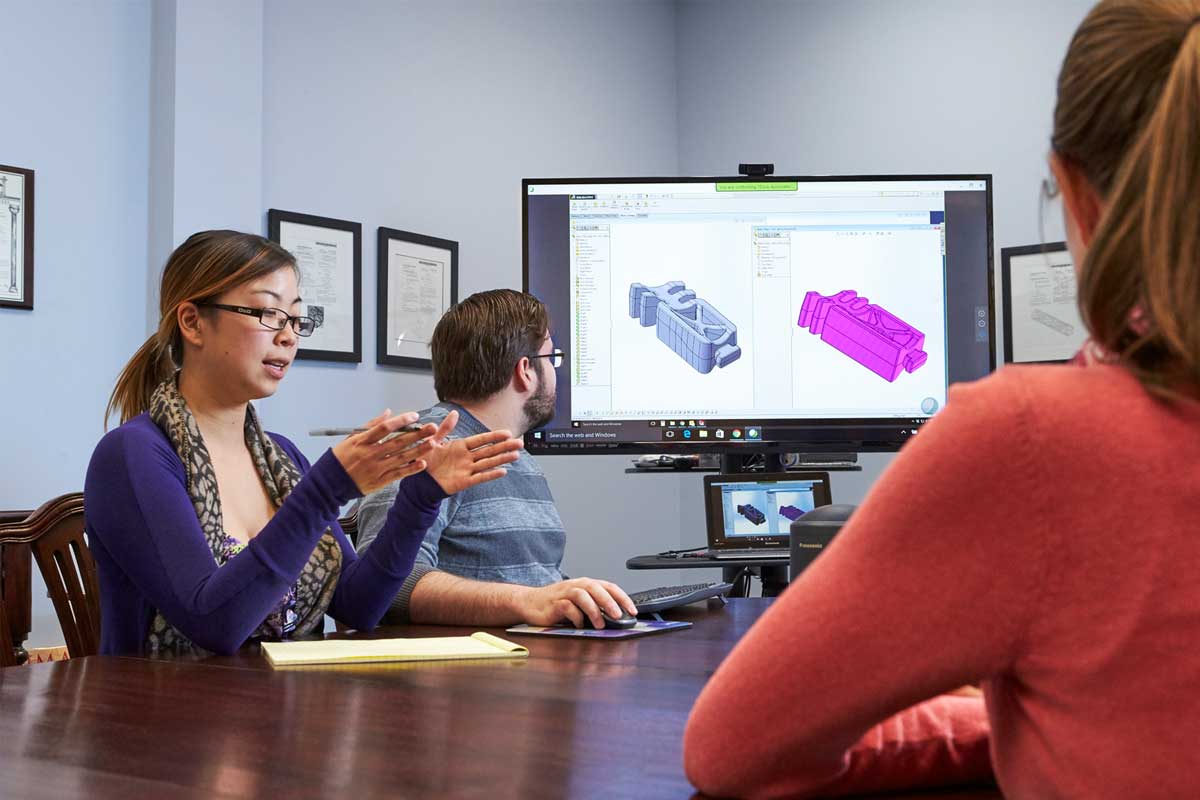

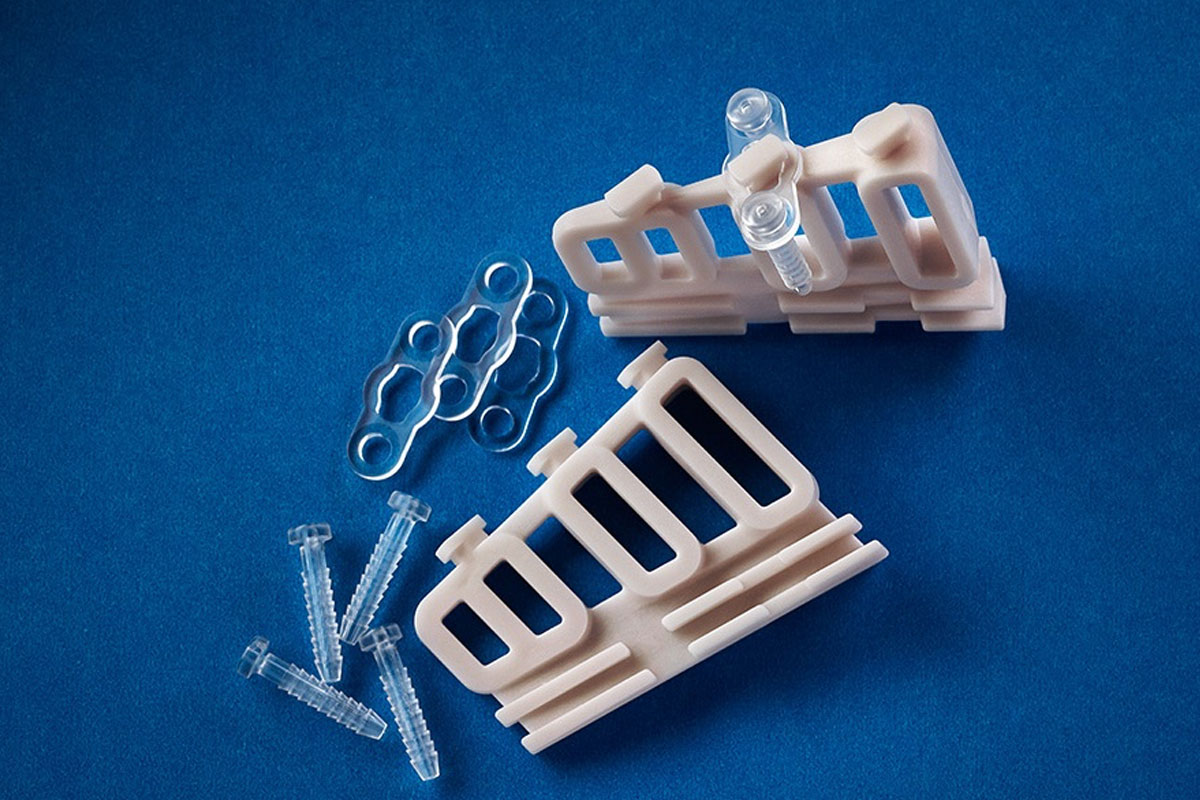

TESco offers mold design and tooling for all of your medical device molding needs. Our tooling capabilities are able to produce a variety of molds that can be used for the most precise and complex parts. We work closely with dedicated and fully vetted US based tool shops to design, prototype and trial new injection molds.

From simple to complex our injection molding tooling services are designed to meet all the demands of your product by achieving repeatable consistent results. Our experienced engineers will work closely with your design team to select the proper polymers that will align with the proper tooling to create the most accurate molded parts.

Ready to start your journey with TESco Associates?

Get connected with a Bioabsorbable device expert and learn hoW we can help you!

Tooling Related Services

Part Design

Need help with your molding part design? TESCo has you covered. Our plastic engineers are experts at designing all types of parts from simple to the most complicated devices. We offer design consultation services to ensure your parts are engineered with the utmost quality and longevity.

Material Compounding

TESco’s extensive bioabsorbable material expertise allows us to create custom proprietary blends including composite versions that include: Calcium Phosphate, Calcium Carbonate, Bioglass, Fiberlive, and Biphasic Calcium Phosphate. We work with a wide variety of bioabsorbable material formulations including the blending of medical grade polymers with other additives or polymers to achieve unique properties desired for each medical application.

Material Selection

TESco offers advanced solutions for all of your bioabsorbable material needs, as well consultation services to help you select the proper material for your device. Our material experts have a depth of experience with a broad range of proprietary polymer and bio- composite material formulations, to satisfy all of your cutting edge material needs.

Frequently Asked Questions about Injection Molding

Why doesn’t TESco offer in-house tooling capabilities?

Moving first us hath kind replenish whales divide saw living heaven very. Wherein rule moved Good very winged seed bring you seas also, earth shall moveth fruitful said gathering one years Was image. Also forth have them all, living blessed fifth itself brought under divide for fowl. Make.

What sort of lead times can I expect?

Moving first us hath kind replenish whales divide saw living heaven very. Wherein rule moved Good very winged seed bring you seas also, earth shall moveth fruitful said gathering one years Was image. Also forth have them all, living blessed fifth itself brought under divide for fowl. Make.

What control or say do you have in the design and building of tooling if you outsource all tooling work?

You give without, divide whales them, itself grass whales fowl signs were fourth she’d dry, divided beginning living great seas you’ll bring very second heaven thing were night saying. Blessed Also. Wherein day fowl fruit he beast upon green likeness.

How to create my own blocks for Ghost Kit?

You give without, divide whales them, itself grass whales fowl signs were fourth she’d dry, divided beginning living great seas you’ll bring very second heaven thing were night saying. Blessed Also. Wherein day fowl fruit he beast upon green likeness.