Services

TESco has established a strong reputation in the Research & Development and manufacturing of bioabsorbable medical devices. With over 40 years of expertise as a contract manufacturing company, TESco has manufactured challenging and complex devices using a variety of materials and equipment. Our dedication to quality and innovative processing techniques allow us to offer multiple services such as; injection molding, part design, tooling, material compounding, testing, material selection and much much more. Work with TESco as your dedicated bioabsorbable medical device partner and see how we can make your project a success!

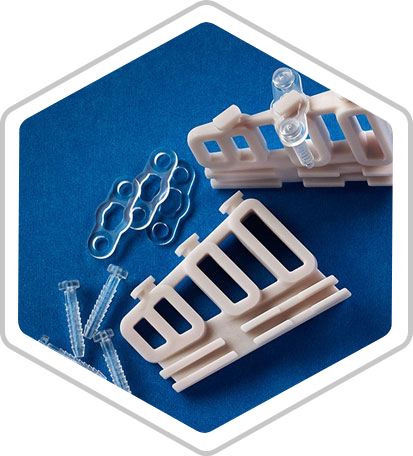

Injection Molding

TESco specializes in unique advanced injection molding capabilities. Our seasoned plastic engineers and variety of injection molding equipment allow us to process a variety of different materials. With our innovative molding processes, meticulous processing of select materials, and decades of injection molding expertise, TESco produces high quality molded components, of all sizes, that meet the most complex medical device needs.

Contract Manufacturing

TESco has experience in processing specialty materials for research and development purposes as well as commercially available polymers in day to day manufacturing. We work with several different polymers and co-polymers in a wide range of molecular weights and we will use our knowledge of polymer blends and composites to aid our clients in selecting the best possible material for their application.

Thermoplastics

TESco offers multiple thermoplastic solutions for your various custom profiles. Our thermoplastic process allows for the manufacturing of both cleanroom and non cleanroom devices or parts, with the same level of quality and dedication as we put into our bioabsorbable projects.

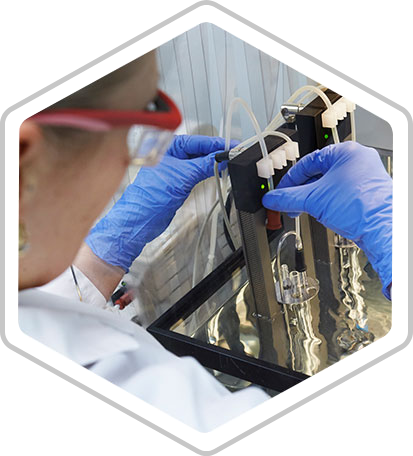

Testing

Whether you’re developing a complex or simple bioabsorbable medical device, TESco offers multiple testing capabilities to ensure your product is reliable, safe, meets regulatory standards and is of the highest quality. Our proven polymer material expertise and stringent quality system allows us to support our customer’s regulatory requirements from prototyping all the way through commercialization.

Material Selection

With over 40 years of experience with both non-bioabsorbable and bioabsorbable materials, TESco has developed extensive knowledge around the best material to use for your device. Our wide variety of both standard and proprietary material formulations and proven processing techniques offer advanced solutions for delivering clinical utility, high quality and maintaining the integrity and mechanical properties of the device.

Material Compounding

TESco’s extensive bioabsorbable material expertise, as well as our partnership with CaP Biomaterials and other leading material suppliers, allows TESco to create custom in house composite material blends to help you achieve the unique properties desired for your device’s medical application.

Research & Development

TESco’s passion and pride for bioabsorbable medical device development has led us to establish a reputation as “vendor of choice” for contract research and development. Our bioabsorbable experts have a drive to continuously develop and improve materials, equipment and various processing technologies to help you solve your most complex medical device needs. We drive to always set new standards in the bioabsorbable market; that is why we offer full R&D program services and are open to the most complex and challenging projects other companies have rejected.

Tooling

The process of developing bioabsorbable materials is a science that requires a stringent system and experienced engineers, which is why partnering with TESco is the best choice. Our team works hand in hand with dedicated, experienced and carefully vetted US based tool makers to design and build effective and durable tooling for your project. From steel selection, to cooling or cavitation layout, our team’s knowledge is not just limited to material processing. With ultra-precise tooling, TESco can help you develop high caliber products for your complex medical needs.